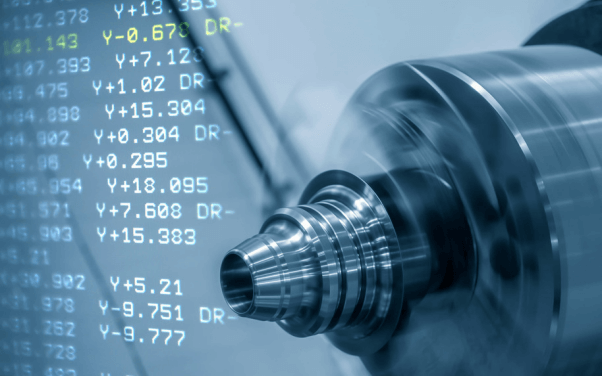

A CNC machine provides advanced pro-combination technology controlled through an alpha-numeric system. And at the base of the device, five significant components have functionality blended into a synchronous system. Computer programmed information is used in controlling and managing the operations of the CNC system.

Every specialist of CNC machining parts in China has a clear understanding of the components and their contribution to the success of the machining process. In this blog post, we take a look at some of the essential machine parts of a CNC machining.

Input devices – function

A CNC system is controlled through a unique specialty system. That is why it is crucial to have an efficient way of coordinating a pre-programmed data coupled with a designed system. The input devices and components are such as flash disks and data transfer components.

Control unit – funtion

At its heart, a CNC’s system has a relatively high-value control panel with a data processing unit coupled with a control loop unit. The system component allows the machine to decode programs easily.

Immediately decoding has taken place, the interpolator resting on that DPU calculates the position of the spindles. When interpreted, data is relayed into the CLU. This is often in the form of electrical signals.

Different machining parts will then initiate smooth movement based on the transmitted signals.

Driving system- function

This is another crucial component of the CNC machine. It responds to the entire pre-programmed instruction of the machine by spearheading the cutting of the machine’s end products into the recommended design.

In its purest form possible, the device has different control motors with a rotation that determines its movement into the spindle.

The Frame- function

The frame of a CNC machine is positioned right above the ground; it is the primary support system of the machine. But, there are different materials for the frame. They include granite or iron that comes in a filled structure. Steel is barely used as a frame since it has a few spring properties coupled with little dampening capabilities.

Although very stiff, iron is still a preferred choice in the framing department. An additional innovative idea is the application of epoxy resins that come in a variety of sizes of stones found in a welded steel container. Epoxy granite makes a damper mixture. When confined in a container made of steel, the strength is improved. Aluminum can also be utilized in creating this mixture.

That said, there are a few significant arrangements made when it is time to put foundation bolts on the frame’s machine such that it is anchored to the ground.

Final Thoughts

Well, there you go! CNC machining systems are applicable to various industrial applications. Some of these industries include metal fabrication, manufacturing, agriculture, automotive, and discharge machining. The guide above is created for learning. This page provides you with the basics of CNC machining and its components. You can use it as an aid to assist you in decision making when it comes to a DIY CNC machining project.