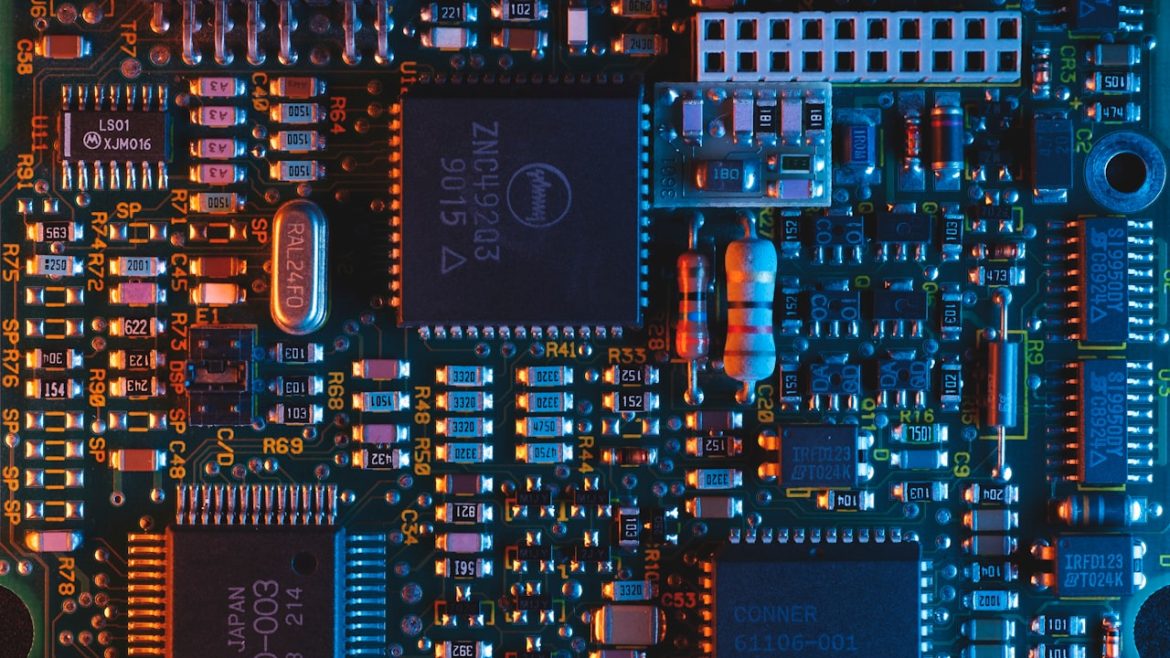

PCB assembly service involves processes where electronic parts are soldered to printed circuit boards. The service ensures that the PCB board is quality and are functional. Some of the best manufacturers available offer the best full PCB printing and assembly service. The services ensure that the PCBs manufactured apply to various sectors. The critical point to note is that the type of material used plays a crucial role in the quality of PCB to expect. Therefore, this post will inform you of the best way of selecting the best material for PCB assembly service.

The best way of selecting the best material for PCB assembly service

1. Check on thermal reliability

PCB assembly service involves soldering on materials. Therefore, different temperatures may be used. Thus, the material used should be able to withstand the required temperature range. Furthermore, the board should be able to perform well at the expected temperature. Standard boards require the materials present to have lower thermal ratings.

At the same time, other particular boards require the materials present to have high thermal ratings. Furthermore, the material used should be able to withstand the needed temperature and atmospheric conditions without overheating. Thus, if you want a PCB for high-temperature operations, the materials must withstand the required atmospheric condition.

2. Ability to withstand stress

Some PCBs are required for sensitive sectors such as the medical sector. Therefore, while selecting a PCB for areas that require special care, it is essential to use materials that can withstand stress. Inappropriate materials used for PCBs in industries such as the medical industry can bring about catastrophic repercussions.

3. Ability to withstand heat transfer

While selecting the best materials for PCB assembly service, it is essential to look at its ability to withstand heat transfer. The board should withstand high heat levels without transmitting the excess heat levels to adjacent or attached components. Therefore, it is essential to test the PCB material on its ability to withstand heat transfer before low volume or mid-volume manufacturing.

4. The flexibility of the PCB

The latest innovations in PCB allow for them to be print flexible circuit boards. Flexible circuit boards are prevalent in disposable sensors and medical devices. Therefore, for flexibility to be attained, you need to choose materials that allow for flexibility, are affordable, and are safe.

5. Check on signal performance

A material’s signal performance is essential in selecting PCB materials. The material used in a PCB should ensure that it can expedite continuous electrical signals throughout a machine’s operating cycle. Furthermore, the material used can withstand a wide range of temperature and environmental conditions.

6. Cost

The materials cost is also essential in selecting the PCB materials. Additionally, the cost present should match the signal performance you expect. Furthermore, the application of your device should play a role in the type and affordability of material. PCBs used in toys are not the same as those used in medical devices. Thus, those in toys could be relatively cheaper.

Conclusion

The materials used in a PCB can determine the durability, safety, and performance of the PCB. Therefore, if you wish to have the best material for PCB assembly service, it is essential to study the various material characteristics.